There’s always a reference to the ERP and the value it brings to the chemical industry. Whether it is the drug, thermoplastic, adhesives, cosmetics, petroleum, coatings, synthetic, or any other industry, there is always going to be challenges of rising global demand, cost management, production planning, chemical compositions, usage parameters, distribution management and so on. To combat all these challenges, there needs to be a system in place that can automate all these business functions with ease. An ERP software specifically designed for this industry supports all GMP requirements and brings major business benefits.

Let’s dive deep and see how an ERP helps to manage the intricacies of the chemical business.

Manage and Record Formulation

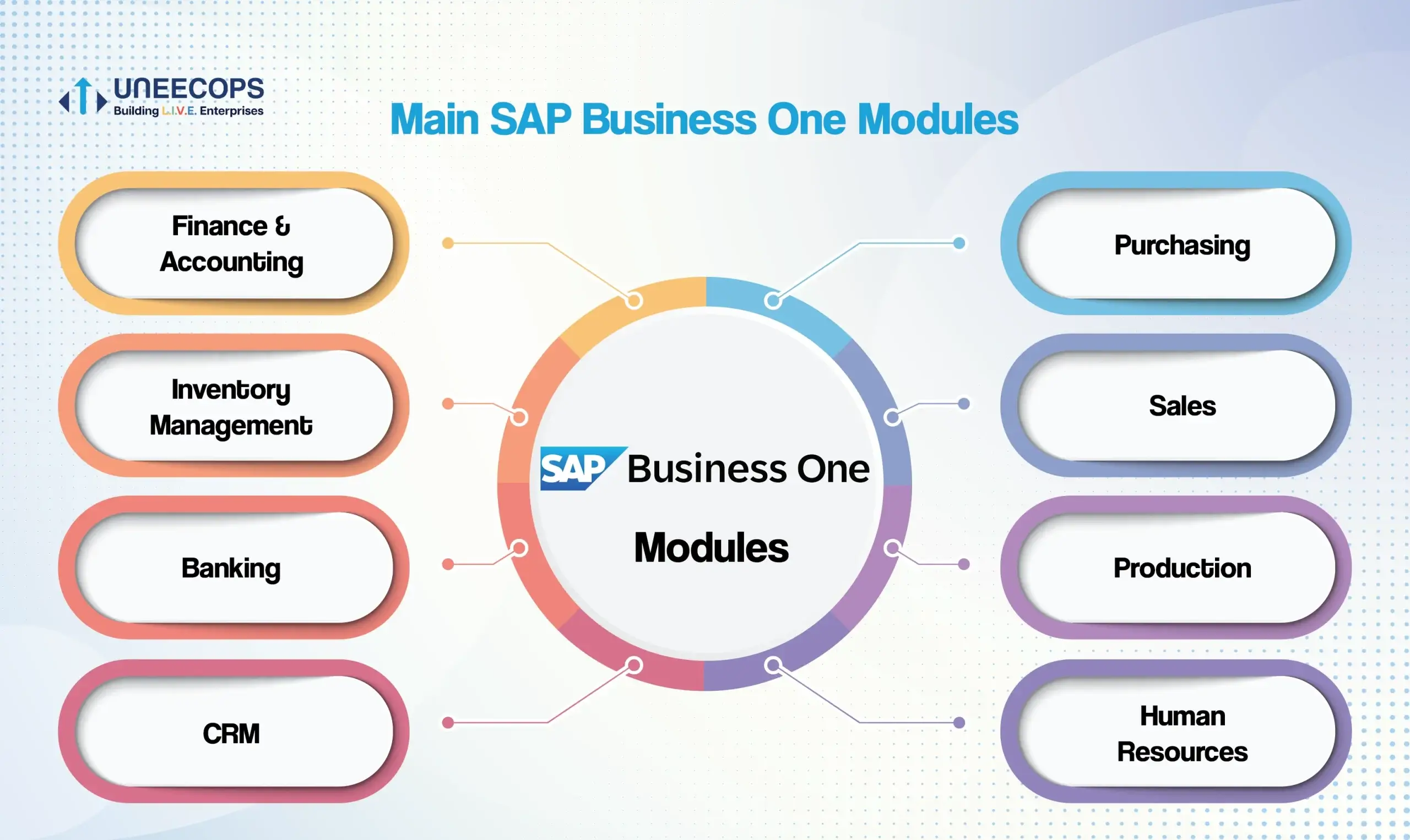

SAP Business One helps chemical manufacturers to keep a record of their formulation. This helps them to exercise great control on quality, improve customer satisfaction and streamline the production process without experiencing any hiccups. The software facilitates to maintain a master batch record for complete trace-ability and precision. It confirms all the ingredients required to complete the process. With this, you can safely track and store unique compositions, confidential recipes and restrict unauthorized access.

Automate Workflows

Quality management is essential to chemical business since the stakes are high. With a smart and robust ERP, you can automate all batch records, processes and workflows to suit your unique business models. This will help you to eliminate any manual flaws, minimize errors and boost the production process with utmost quality. Further, this intelligent software boosts collaboration and improve interdepartmental relationships.

Lot Traceability

SAP Business One facilitates the Lot number generation. This helps manufacturers to keep a tab on all possible lots at the time of receiving, in transit or finished goods. The software assigns a unique identification number to the raw materials lots and makes tracking of byproducts, waste age and shelf life little easier.

Scale up Production Process

The ERP dynamically adjust the specs and yields as it views the inventory available on stock. Further, the software auto links and schedule batch jobs to expedite the production process. This software also helps to plan well in advance of all chemical formulas, binding, and resources available based on MRP and lot size.

Dashboard and Reporting

The dashboard of SAP Business One gives a crystal clear insights of all critical data, inventory consumption, batch lot, planning and scheduling, total expenses, savings, the shelf life of chemicals and upcoming sales trends.

Gives a 360 bird’s eye view

The ERP software enables all chemical business manufacturers to view standing orders, sales orders, batch production jobs, supplier information, weight units, volume units (e.g. gallons, liters or milliliters).

SAP Business One empowers your business to easily manage store replenishment, lets you execute critical activities like processing raw materials, waste management, expense management, inventory tracking and planning. stock handling, delivery management and many other aspects.