Introduction/Overview

Modern markets are profoundly volatile. Both big and small companies are constantly on their toes to meet customer expectations, perfectly ascertaining their inventory, sales and supply chain levels. Inventory is the core of all ecommerce operations. And in today’s e-commerce generation, SMBs to enterprises are seeking better, efficient and automated approaches to keep inventory visible, organized and sufficiently stocked.

Amidst the supply chain hue and cry, leaders who focus on inventory optimization as a strategic differentiator and profitability driver more than an operational function will enjoy a better competitive edge.

Why did we mention inventory optimization and not inventory management? Are these not the same? No, because inventory optimization is a strategic multiplier of profitability. Inventory management was more a tactical planning exercise to mitigate risks, but 2025 requires CEOs to optimize their inventory to reduce costs, forecast demand, and tweak supply chains to improve direct financial performance. Inventory optimization requires aligning supply with demand while optimizing resources to enjoy competitive advantage and leverage a direct impact on ROI as well as a company’s shareholder value.

Now, the practical question is, how to undertake supply chain inventory optimization management? What are the ways to optimize inventory? Let us dive deep!

What is Inventory Optimization?

Inventory optimization helps a company plan its stock levels based on rising and falling customer demands to ensure that there is minimal wastage, storage cost, and risks of under or overstocking. The right inventory level needs some buffer for unforeseen demand or market disruptions, but avoiding surplus is what inventory optimization is all about. It is a practice that involves a thorough SWOT analysis and preparing for future inventory in a manner that there is ROI, cost saving, and improved customer satisfaction as clients get products available when they demand them.

Beware, do not confuse the two terms – inventory management and inventory optimization.

The Differences Between Inventory Management and Inventory Optimization

| Aspect | Inventory Management | Inventory Optimisation |

|---|---|---|

| Definition | A broad function focused on ensuring efficient inventory operations | A focused subset aimed at maximizing financial returns from inventory |

| Position in Inventory Control | Lies under inventory control as a major operational area | Subset of inventory management; key component of inventory control |

| Primary Goal | Achieve productivity, operational visibility, and efficiency across inventory processes | Minimise waste, reduce costs, and maximise profit through accurate demand forecasting |

| Key Activities | Stock tracking, procurement, warehousing, logistics, supply chain visibility |

Demand forecasting, stock level optimization, risk balancing (overstock vs. shortage) IoT, AI, cloud systems, robotics, automation Predictive analytics, machine learning, financial modelling |

| Impact on Operations | Enhances coordination across departments and ensures process efficiency | Directly influences profitability, customer satisfaction, and brand trust |

| Typical Risks Addressed | Stockouts, delays, process inefficiencies | Overstocking, obsolescence, missed sales due to stock shortages |

Modern Day Challenges in Inventory Optimization

Today’s companies face these key bottlenecks when it comes to their supply chain:

- Stock level: Ensuring optimal inventory levels to avoid insufficient or excess stock

- Production level: Mapping and matching production level to market demand (and accordingly storage and logistics)

- Unanticipated problems: Unforeseen events such as raw material procurement delays, supplier problems or shortages, transportation challenges or natural disasters can affect the inventory and disrupt the entire supply chain. Fluctuations in market trends, geopolitical tensions, customer demand, and seasonal spikes can also affect inventory management.

- Traditional tools: Legacy systems can affect inventory data tracking efficiency and cause vague decision-making, due to a lack of valuable data insights.

- More and more competition: Industry 4.0 implies that businesses can set up and grow faster than ever. Online platforms have provided scale to businesses but also the challenge of catering to more customers. But the same has also increased business competition, further amplifying the need to supply better products on time.

This is what we’ve discussed and what is known about the limitations of inventory management. But, to optimize inventory, we need to understand the implications of these bottlenecks. Let’s dig deeper.

- Inventory mismanagement can significantly impact operational efficiency and financial performance.

- Overstocking ties up working capital in excess inventory, increases inventory holding costs, and compresses profit margins due to storage, insurance, and depreciation expenses.

- On the other hand, understocking leads to inventory stockouts, resulting in lost sales, unmet customer demand, and long-term damage to customer satisfaction and brand reliability.

- Production slowdowns and workflow inefficiencies further reduce order fulfillment rates, even when sufficient inventory exists, due to poor alignment between inventory availability and production capacity.

In sectors dealing with high-value, slow-moving goods or customized product lines, maintaining optimal inventory levels becomes essential. Challenges such as long supplier lead times, fluctuating demand, multi-tiered assembly processes, and quality control delays add pressure on the supply chain, leading to friction across planning, procurement, warehousing, and distribution functions.

For sustainable growth, businesses must adopt intelligent inventory planning, leveraging demand forecasting, real-time inventory visibility, and data-driven supply chain analytics to balance service levels with cost efficiency.

Why Inventory Optimization is Important in Today’s Times?

Did you know? The Costs of Overstocking or Understocking Inventory Can Be Huge – Hitting Business Profitability

The costs of excess or limited inventory can be huge. Let us do simple math for excess inventory for example. Imagine a huge and successful heavy machinery manufacturer in India holding four weeks of inventory to ensure production uptime. With high-value components, this inventory could easily be worth ₹800–850 crore.

By reducing coverage from four to three weeks, the company can save up to ₹550 crore annually in inventory carrying costs. Over two years, that’s ₹1,100 crore in direct savings. This far outweighs the cost of any tech upgrade, implementation, or training.

Even companies with smaller inventory values can justify a visibility solution purely on the back of carrying out cost savings.

What could be this company’s inventory carrying costs?

They include:

- Interest on blocked working capital

- Lower insurance and taxes

- Reduced manpower and handling

- Smaller warehouse space

A conservative benchmark is 20% per annum, but most companies underestimate this number, and apply it uniformly across SKUs, which often hides inefficiencies.

The takeaway: Reducing excess inventory isn’t just smart; it’s a strategic lever to unlock massive value. Similar math applies to limited inventory also. Thus, inventory optimization becomes a key learning curve for all managers and decision-makers.

While the above is a hypothetical example, you can surely imagine the cost and impact of mismanaged inventory for your MSME to large organizations.

Now, discussing 2025 and the times ahead, inventory is particularly a key consideration, that is on top of C-suite’s priority as it is susceptible to political, social factors, natural events, economics, and business competition. Moreover, just as people have low attention spans nowadays, so is this era of 10-minute deliveries.

What does this mean for businesses? It mean the client tolerances for delivery times are lean.

E-commerce giants have made same-day and next-day delivery the norm, and this has had a colossal impact on inventories of enterprises as businesses now need multi-locational inventory management.

There is one more thing to consider. These days, brand loyalty is fading as new brands are mushrooming, and online shopping is taking over. The tremendous competition calls for businesses to optimize their inventory or stake profit margins by huge percentages.

Now, we have come to the primary part of the article. The ways to optimize inventory. Let us go through the top inventory management techniques and best practices.

What Does Inventory Optimization Entail?

Effective inventory management spans multiple interconnected functions that ensure seamless supply chain performance. It starts with requirement planning, where businesses forecast demand, set stock levels, and align sales cycles. Procurement involves managing purchase orders, supplier relationships, and cost-effective sourcing. Production planning ensures raw materials are available and synced with manufacturing schedules to avoid stockouts or excess. In sales and distribution, inventory is tracked across locations to fulfill orders on time. Quality management safeguards standards through material inspections and defect handling, while plant maintenance relies on tracking spare parts to prevent downtime. Together, these functions help maintain optimal inventory flow, reduce waste, and boost operational efficiency. The infographic below highlights this process and its steps clearly.

4 Best Ways to Optimize Inventory

Accurate inventory optimization leads to more efficiency, reduced errors, and faster turnaround times. Here is how this can be done:

-

Demand Forecasting: In the period of AI, you ought to ascertain future demand for products to make more informed decisions about what customers will want in the upcoming seasons, weeks and years. It is a strategic move to plan inventory and related processes, such as resources, procurement, production, inbound logistics, financial planning, and risk assessment.

An AI-based ERP, Analytics or CRM solution can help enterprises optimize inventory, plan production and efficiently handle supply chain. They can also reduce the chances of excess inventory costs or missed sales opportunities.

For example, a crocks footwear manufacturer can begin to add 20% inventory before the rainy season as fashion trends could favor his business then. He can plan discounts in the winter season and use inventory management systems to automate this demand prediction procedure.

-

ABC analysis: This is a method of identifying the most and least profitable products based on their value and sales – where A products are the top prices, low selling products that need inventory control and monitoring, B products are moderately demanded products that need relaxed oversight and C is the least value, high-moving products that need planned re-stocking.

Using historical analysis, smart technologies help demarcate the high-value and low-value times to anticipate rising and falling inventory. Besides, it also enables business owners to focus their resources and production toward high-priority stock while reducing excess inventory.

-

Inventory Turnover Ratio: Inventory turnover ratio is used to calculate the number of times inventory is sold and re-stocked in a certain period, which is usually measured annually. A simple formula is used to calculate this:

Total Cost of Goods Sold (COGS) ÷ Average Inventory Value = Inventory Turnover RatioTo make this easier to grasp, imagine a home appliance retailer that reported ₹12 crore in cost of goods sold (COGS) over the past year, while maintaining an average inventory worth ₹2 crore. By applying the inventory turnover formula, the result is a turnover ratio of 6, indicating the inventory was sold and replenished six times during the year.

While the “ideal” turnover varies by sector, a range between 6 and 11 is generally considered healthy for most retail businesses. Industries dealing with fast-moving or short-shelf-life items like food, cosmetics, or pharmaceuticals often strive for even higher ratios to minimize spoilage and storage overhead.

A low turnover ratio may hint at slowing demand, prompting price cuts or product tweaks. A high ratio suggests efficient sales but could also flag supply risks or stockouts—often leading businesses to boost orders, adjust pricing, or expand their supplier base.

-

Safety Stock Calculation: No business wants a stockout situation. It affects their sales, operations, and reduces revenue. They also run the risk of losing customers to their competitors. Thus, safety stock is required. But how much safety stock is just apt – that it does not translate into excess inventory? That is exactly the work of smart technologies. They help determine buffer stock that allows companies to meet sudden demand surge.

Traditionally, business owners also use a basic thumb rule to maintain backup inventory – typically multiplying their average daily sales by a pre-decided buffer period. For instance, if a business moved 150 units daily and aimed to cover 10 buffer days, it would stock 1,500 extra units.

However, this simplistic approach often falls short in today’s volatile markets. Smarter inventory strategies now factor in variables like supplier reliability, seasonal shifts, and real-time demand variability. By incorporating lead time variability, service level targets, and recent sales trends, businesses can better optimize their safety stock, ensuring they are protected from supply chain hiccups without tying up too much capital in idle inventory. Modern inventory planning is no longer guesswork; it’s data-driven resilience.

Best Practices for Inventory Optimization

The following are some additional ways and best practices for effective inventory optimization:

- Materials requirements planning (MRP) tools: Earlier, manufacturing businesses used legacy MRP systems to assess, organize, schedule and control inventory. Nowadays, legacy MRP tools are replaced by integrated and demand-driven MRP (DDMRP) systems to ensure the right stock is maintained as per production and delivery schedules. Modern MRP software tools help forecast demand, coordinate purchasing and delivery of materials, and manage Bill of Materials (BOM).

- Perpetual inventory systems: For fast-moving consumer goods (FMCG) that move at lightning speed, technologies also need to update at lightning speed. That is exactly what smart perpetual inventory management tools do. They automate the end-to-end omnichannel purchasing touchpoints using AI and machine learning to ensure live stock insights and accurate warehouse to logistics status updates.

- Reorder point formula: Another best practice is to adopt the recorder point formula for inventory management. It is usually used by retailers to ascertain the minimum inventory before they need to reorder. Every good, however, has a different reorder point based on sales and demand. This is where inventory optimization software helps manage multi-locational and multi-SKU inventory levels in real time.

- Always keep safety buffers: Business is never linear. Unexpected events can cause inventory demand to rise or fall sharply. Business owners must maintain a realistic stock buffer to ensure there is no loss of income. In both cases – shortage of inventory and overstocking (wastage of inventory), the business suffers. The best practice is to maintain optimal inventory – just right. But, how do you know that? The new-age supply chain software solutions connect stock, orders and warehouse data in real-time and perform advanced analysis of inventory management. They give insights on the right amount of excess stock to maintain. This helps businesses navigate much of their margins with impressive accuracy. Although sudden events, like the COVID-19 pandemic cannot be foreseen, these tools help primarily in predicting demand based on such events.

- Focus on inventory budget in Q1 planning: Always remember to create an inventory budget at the beginning of the year and review the budget quarterly. This way, you have an overarching plan when you start, and you can set targets and goals accordingly, but also you will be able to optimize inventory based on business cycles and shifts throughout the year.

- Continuous or periodic review system: Like we discussed above, setting an inventory plan and budget at the beginning of the year is critical, but equally important is to ensure the inventory plan is reviewed monthly or quarterly to improve efficiency, replenish stock when needed and reduce wastage.

- Consider your customers. If you use the best inventory management software, it will get you buyer patterns and sales data – as well as recommend how much inventory is required based on demand. This is the best practice to optimize inventory – based on data and real-time insights.

- Use just-in-time (JIT) and on-demand principles. In 2025, just-in-time (JIT) and on-demand inventory strategies are no longer optional; they’re essential. With product lifecycles growing shorter and consumers expecting speed, personalization, and zero wait time, inventory optimization must be real-time, data-driven, and highly agile. Technologies like 3D printing, robotic automation, and digital twins now enable businesses to hold virtual or near-zero inventories, fulfilling demand dynamically. Manufacturing and logistics ecosystems increasingly rely on flexible, on-demand supplier networks, reducing the need for stockpiling. Empowered by AI-driven software, inventory planners can now make instant, insight-led decisions, adapting to demand shifts with precision and confidence.

- Adopting cloud-based and automated inventory tracking software solutions: These inventory optimization tools provide integration with procurement, warehouse and sales systems like enterprise resource planning (ERP), customer relationship management (CRM) tools and point of sale (POS) systems to showcase a unified view and tracking of stock. They also leverage automated barcode scanners, RFID technology, and AI-powered tools to enhance data accuracy.

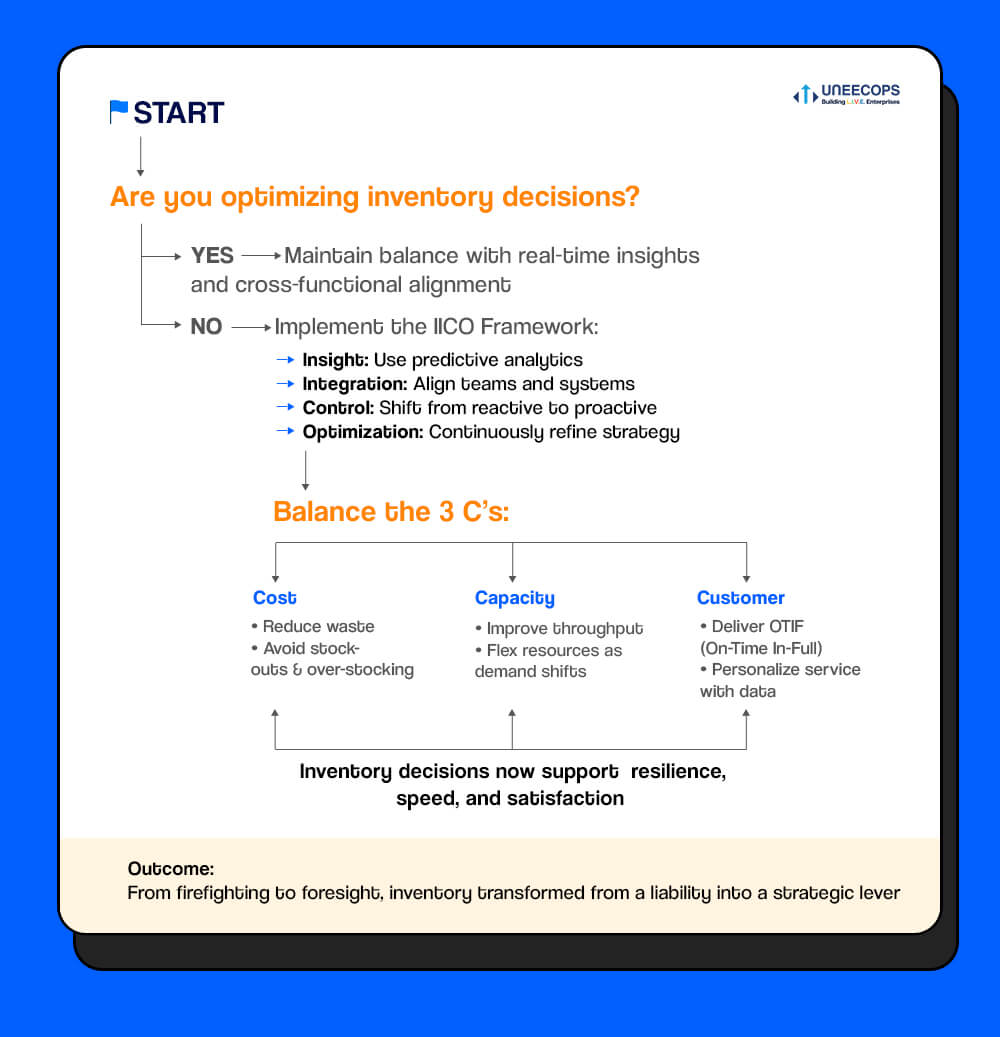

The 3 C’s of Strategic Inventory Optimization – Proposed by Uneecops

To navigate effective inventory optimization, organizations must anchor their inventory strategies around the three critical pillars: Cost, Capacity, and Customer. Together, these “3 C’s” help businesses optimize inventory decisions not just for efficiency, but for long-term resilience and market responsiveness.

- Cost

Effective inventory management directly impacts cost by reducing waste, minimizing overstocking, and preventing stockouts. Carrying excess inventory ties up working capital and incurs storage, insurance, and depreciation costs, while insufficient stock leads to missed sales opportunities. By leveraging accurate demand forecasting and data-driven planning, businesses can maintain optimal stock levels and improve profitability through smarter cost control.

- Capacity

Optimizing inventory helps enhance operational capacity by aligning inventory with production schedules and resource availability. This enables smoother workflows, minimizes idle time, and boosts overall throughput. As demand fluctuates, agile inventory planning allows organizations to flex production and warehousing resources efficiently, ensuring that capacity is utilized without overburdening systems or causing delays.

- Customer

Inventory management plays a crucial role in delivering a seamless customer experience. Meeting On-Time In-Full (OTIF) delivery targets ensures reliability and builds trust. By maintaining the right inventory levels and using data to anticipate customer preferences, companies can personalize offerings, reduce lead times, and improve satisfaction — ultimately turning inventory accuracy into a competitive advantage.

The below infographic highlights how to use these 3 C’s of inventory optimization can be practically used for business value:

The future of Inventory Management: AI-Powered Inventory Optimization Techniques

For any businessman, the ideal scenario would be a world where his inventory meets all customer demand, and he goes back home without the worries of pilferage or perishability issues. In the AI age, this is demonstrably possible. Now, the business dream can be reality, and hospitals do not need to worry about running out of injection doses, retail shops don’t have to be bothered lack of seasonal or running ration items and farm produce is able to reach city consumers without wastage/spoilage.

How can AI help with inventory optimization? According to Gartner, AI holds transformative potential in supply chain optimization, enabling more accurate demand forecasting, reducing waste, and fostering responsive, data-driven planning. This results in measurable cost savings, especially for retailers.

But, Gartner also highlights that 41% of businesses rely on manual methods, 26% use and 26% use third-party software for their daily inventory tracking and stock distribution.

Like we discussed in the challenges of inventory management, festive season demand surges cause retailers to slog to predict demand accurately using traditional methods. Imagine ordering a washing machine during Flipkart big billion days, only to be informed after 1-2 days that the product cannot be delivered as it is out of stock. Such occurrences diminish brand credibility and impact sales. They weaken consumer trust and negatively affect the bottom line.

But with AI and predictive analytics tools, supply chains are more intelligent nowadays.

AI-powered inventory management reduces demand forecasting errors by up to 50% leading to lower stockouts and overstocking. AI also adjusts stock levels in real-time based on sales, city-wise demand, unexpected disruptions, competitor pricing, market trends, weather conditions, and seasonal festive demand spikes.

Real-life Examples and Use Cases of AI-powered Inventory Optimization: India and Globally

BigBasket: One of India’s online grocery platforms leverages AI to tap customer purchase patterns, foresee regional stock demand, and automate warehouse restocking, ensuring that fresh grocery is delivered without much spoilage. AI-driven inventory optimization has helped BigBasket reduce wastage by approximately 35% and considerably improved their order fulfillment rates.

Dr. Reddy’s Laboratories: India’s top pharma firm has deployed AI-powered inventory optimization to handle stock allocation, lessen stockouts and make critical medicines/drugs available where they are demanded with minimal delays.

Apollo Hospitals: The Indian hospital chain capitalizes on AI-powered tracking to manage and distribute drugs across its entire network of hospitals. Foreseeing demand for certain medicines and surgical equipment has minimized emergency stockouts while lowering huge invariable inventory costs.

Flipkart: India’s e-commerce giant uses AI-based inventory management to tap into buyer browsing patterns, purchase histories, and social media searches to stock high-demand products in region-wise warehouses. This has significantly contributed to lesser order cancellations and improved delivery TAT during top-demand shopping times of the year.

Walmart: The U.S. retail giant leverages AI-driven demand forecasting to dynamically manage inventory across thousands of locations. By processing real-time sales data, Walmart has successfully reduced stockouts by 30% and significantly cut down on overstock-related expenses.

Amazon: The American multinational employs AI to automate restocking decisions, cut inventory carrying costs and ensure near-immediate delivery of in-demand products across its global fulfillment centers.

Smarter Supply Chain and Intelligent Inventory Optimization – The Future

AI-powered inventory optimization is a strategic advantage in 2025 and beyond. A tech software backbone with AI-driven inventory optimization can help businesses tap into the future of supply chain management while slashing costs, enhancing order fulfilment responsiveness and accuracy.

With Indian government also promoting AI adoption across industries as a part of its 2025 Budget Announcements, organizations have a golden opportunity to digitally transform their inventory infrastructure with more intelligent, resilient, and efficient supply chain ecosystems. The time to optimize, digitize and modernize inventory is NOW.