Enterprise Resource Planning. It’s fascinating because these are three independent words (and worlds) that come together to make an entire ecosystem in itself!. It’s like creating a new business nucleus where standardization and modernization rule the roost. At a high level, for companies looking to achieve better business outcomes, ERP project is considered one of the prime means to improve outcomes.

Why do we say so? Because ERP, in its real sense, would mean EVERY RESOURCE PLANNED! Right from the supply chain to the shop floor, from HR to accounts payable and everything in between.

Theoretically, this sounds like a solution to most problems. It’s like magic. But ask those who really get to the implementation. Some take years, end up increasing their budget 10X and have their CPAs skyrocketing. Many times, ERP implementation failure is a sad reality.

According to Gartner, the ERP implementation failure rate is almost 75%! In fact, McKinsey estimates that over 70% of all digital transformations fail.

Scared, already? Well, before you go, read more about ERP implementation failures and ERP implementation success stories.

1. Lack of proper planning leading to ERP implementation failure

Project schedules are essential to avoid ERP implementation failure. Some companies try to fasten the process in a bid to get ROI faster. They tend to back-schedule the implementation go-live date. Then, many details are missed and ERP implementation failure rate increases.

In 1999, the global manufacturer of chocolates and sugar confectionery Hershey Foods Corporation faltered during the final leg of the ERP implementation. They started revamping their software infrastructure in 1997 when their operations were scaling worldwide, and they needed a system to align processes. Hershey opted to quicken the process and opted for the Big Bang go-live of ERP. It implemented many modules in one go, most of which could not even be tested appropriately due to a lack of time. Top it all up, this was being planned in the holiday season! There were obviously going to be issues in order fulfilment and process management. Hershey failed to fulfil orders to distributors and retailers despite having stock in their warehouses. Thus, the company’s stocks crashed, and revenue dipped in the final quarters of 1999.

For a project of this scale to be implemented in a company with global operations, plans need to be in place, and timelines have to be prioritized. Within a short time frame, ERP implementation failure is bound to happen. Employee training for the new system also becomes a key challenge.

However, Hershey quickly rebounded and implemented SAP ERP by September 2002, much below the estimated budget and before the schedule. They appointed a new CIO, under whose leadership thorough software testing and robust implementation were executed. Many other factors led to the implementation failures initially and success later on.

Hershey failed ERP implementation is a classic case. But the world had lessons to learn.

Today, there are more problems as times changed and complexities increased.

2. When the ERP ‘MEANS’ for problem-solving and automation becomes the ‘END’

As the ERP project is passed in the company for data migration and implementation, the ERP “MEANS” for centralizing resource planning can turn into the “ENDS,” meaning that the IT department feels the aim was to only install ERP.

Thinking of ERP as an implementation or IT project is in itself the beginning of disaster. From the beginning, ERP should be a mindset – it should be recognized as a solution that needs a continuous improvement approach to optimize your processes. That will surely bring down the ERP implementation failure rate.

3. When your business data fails ERP Project

Ultimately, ERP is a powerhouse of all your enterprise’s data- leads, inventory, employee, and customer data. So, if you are not able to align data properly, you’d say, ‘My ERP implementation idea was vain.’ At this point, complaining about ERP failure is like shrugging blames!

4. ERP is considered a complex system

It is only after implementation you realize that the highly integrated ERP system is also complicated. It is like that airplane dashboard with so many controls and displays. ERP is similar, with dashboards and workbooks even bigger. There is so much you can do. If not, ERP implementation failures are bound to happen, and ERP implementation failure rates are sure to rise.

5. Implementation blown out of timeline and budget

Sometimes, the organization spends millions of dollars implementing ERP and misses deadlines due to several reasons.

6. Not testing

When Hershey failed ERP implementation, it was due to them shortening the testing stages to meet an extremely aggressive deadline. Post go-live, the whole ERP implementation fell out of CRM and supply chain management systems, and Hershey’s profits dropped. Had proper testing been done, disaster could have been prevented.

7. The leadership

Like Hershey’s case, when the right people to tackle ERP implementation step in, everything falls into place.

It takes a strong leader to hold people accountable and keep everything on track, so ensure you have someone with ERP implementation experience leading the project and your team.

Now, notice something VERY important:

In each case that ERP implementations fail, does the system fail or the software? Whose real failure is it?

ERP implementation failures are mainly due to poor management issues, as mentioned and discussed. Even the “right” software will fail without the right data, the right thought process and the right people to carry it forward.

Turning the bane into a boon requires us to break free and think of ERP as a continuous process. In his book ERP Demystified, author Alexis Leon quoted,

“ERP is first an attitude; second, a process, and only third, a set of tools.”

So instead of considering it as a system to be put in place, take it as an organizational cultural change project. Transformation is not always related to technology or infrastructure.

Success in 2024 and beyond demands preparing early on for things that become relevant in the later project phases; training is an excellent example. What’s an ERP implementation project if the employees do not know how to use their newly installed system (which works absolutely well).

What we’re trying to say is simple. Before you get excited about the benefits of ERP – streamlined processes, top and bottom-line growth, enhanced efficiency, data automation, etc., remember not to get too excited! The problem arises when a “hurry up and get things done” approach is adopted. Unless you have a proper understanding of your business goals, how would there be ERP implementation success stories?

It is, therefore, in your best interest to take the time to understand how your business actually runs. It is also critical to understand the level of resource commitment the project will take, for example. That’s what we spoke about when we mentioned proper training and leadership to steer the project. A cultural mindset.

The checklist is simple –

- Focus on business data quality for ERP to make sense.

- Begin ERP implementation when the culture is strong enough to embrace process change.

- Put experts on the project. Hire a partner if needed.

Power of Partnership (and People)

Large, extensive, complex projects need superior skills and proficiency to establish plans, paths, and goals to hit the industry standards, as well as stay the course to successful execution.

You need to be clear about your existing challenges, where you want to go, your budget, required resources and time frames to build a winning ERP implementation plan. Now, you can sure be the jack of all trades, but you need a king to steer such complex projects.

Many enterprises feel confident navigating the initial phases of their ERP deployment but need additional assistance from vendors/providers in the later stages of the process. As a leading ERP provider and India’s #1 SAP ERP Platinum Partner, Uneecops helps you through the planning, data migration, training, go-live and maintenance stages.

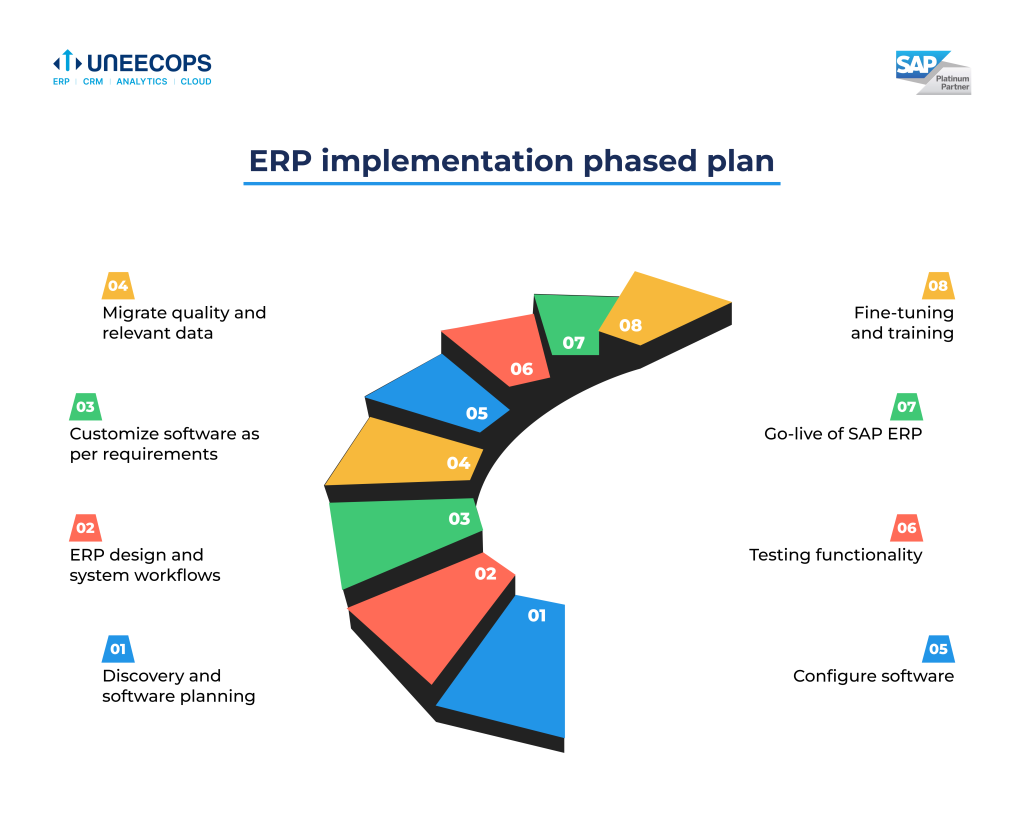

Here is our ERP implementation phased plan, in a nutshell:

The future is brighter for those who plan ERP and prep their organization culturally for the change in ways of working. To bring in automation, you need someone to drive the agenda with a vision. You need a partner that puts your needs first and goes the extra mile to understand your business. With Uneecops, you get the most out of your ERP investment to streamline operations and achieve efficiencies for evolving business market needs.

So, are you ready to turn lessons learnt from failures to carve your path to success? Begin now!