Inventory is an aspect of every industry. The understated fact is that there is a very thin line between this aspect becoming an asset or a liability. When managed properly, it will be an asset; on the other hand one tiny management mistake can spiral out of control and turn into a liability. Instead of paving the way towards profits, ineffective inventory management can drag the company back.

SAP implementation partners in India say that inventory management is no mean task, regardless of the size of organization. Companies should not get overwhelmed by complexities and sundry challenges that come with handling and supervising inventory. Unfortunately, companies end up making some common mistakes that eventually result in emptying their pockets and shelling out more money than anticipated. If these mistakes continue for a long time, it leads to major losses in financial as well as resources. Let us see three common inventory mistakes that every company should avoid:

Not maintaining a database

Not knowing what goes on in inventory is definitely not advised. Inventory does not mean storing the raw materials and manufactured products in a warehouse or shelves. One has to know what exactly is kept at which place, quantity of stored materials, details of vendors and supply chain partners etc. Obviously, an employee cannot memorize all this data; neither can it be written in random memos or physical files risking its safety. Every department, especially in a manufacturing or Food &Beverage industry has to maintain a dedicated database for each section. The database gives a clear idea of what has to be ordered, when does it have to ordered, what products have to be stored, where do they have to be shipped, etc. This will reduce any kind of confusion, manual errors and additional costs.

Forecasting the upcoming demand inaccurately

Market runs on the demands of customers. Based on these demands, companies have to produce their products. Accordingly, they order for raw materials in advance and manage inventory to last through the production. However, SAP B1 partners warn that one wrong forecast can agitate the entire inventory. One scenario will occur based on where the prediction tips – either there will be surplus or a deficit. The former will result in excess of unused raw materials or unsold finished products and the latter will result in non-fulfillment of customer orders and hit sales. Both the scenarios end in heavy losses for the company. SAP solution helps in preventing this mistake by studying the market, understanding its dynamics, generating reports and providing necessary insights.

Resisting new technology

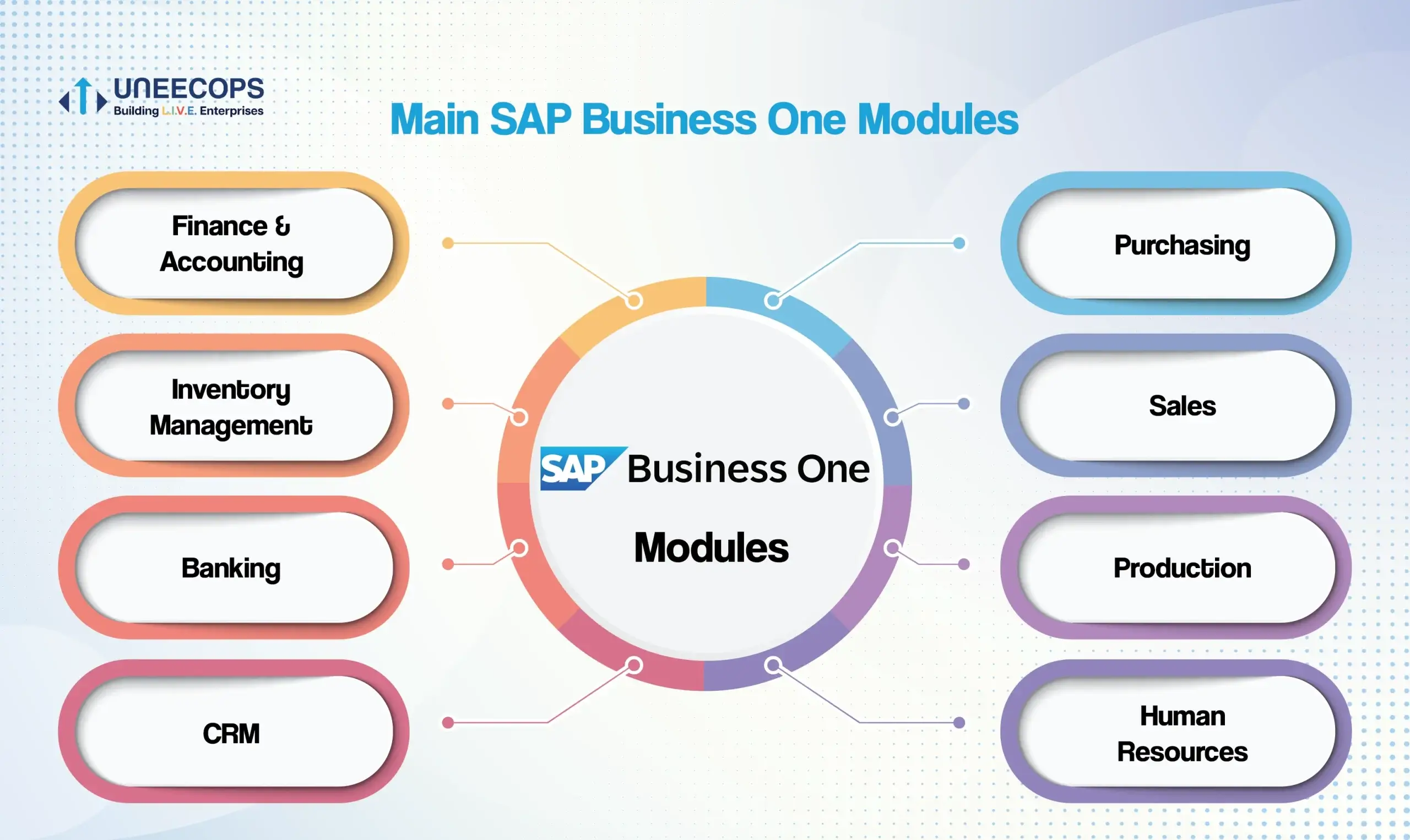

One of the biggest graves that companies can dig for themselves is not keeping an open mind about new technology; especially the ones that can help them take giant strides towards success. SAP implementation partners in India assure that technology such as a new ERP system; new modules or even upgrades will greatly help companies in different areas. Inventory management has various nuances and zones that need meticulous management techniques. The advantage extends to high accuracy, an increase of quality, obtaining a level of ease in performing various operations and high optimization of materials and resources. Technology would also assist in handling inventory from multiple vendors, utilizing the warehouse space properly and better analysis of distribution and supply chain management.

SAP B1 partners can put across a long list of why and how inefficient management of inventory can affect the company. Besides heavy financial losses, there will be a drop in the quality level of manufactured goods. Performance of a company as well as its employees will go down. Confusion regarding the whereabouts of materials will waste precious time, frustrate the staff and bring the overall morale down. It will also impact customer satisfaction if the overall sales and quality of products goes south.

An efficient inventory management system will be a good start to the succeeding organizational processes. As they say, well begun is half done – so don’t hesitate to invest in a good SAP solution incorporated with an inventory management module.