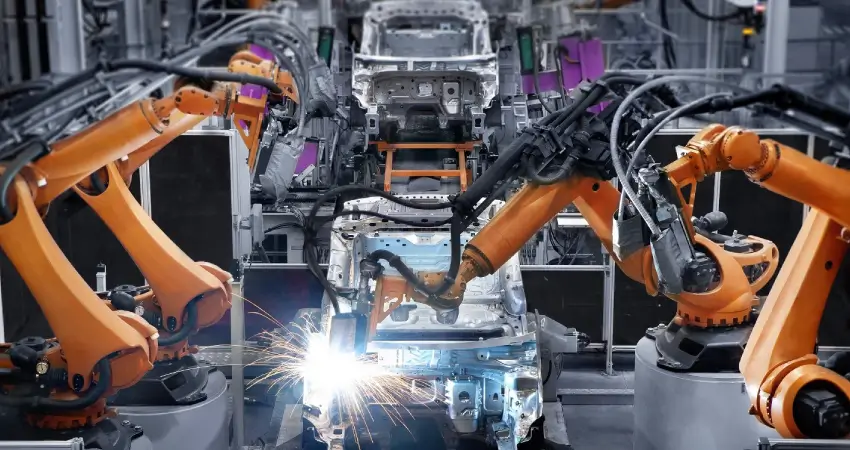

Automate routine tasks with time-tested manufacturing ERP software India

A complete solution for managing the entire gamut of manufacturing processes such as batch costing, production planning, raw material costing, and more industry-wide. Designed for small and mid-sized discrete and process manufacturing companies, this SAP ERP for manufacturing industry can manage every aspect of your manufacturing operations seamlessly. Find out how Uneecops is enabling manufacturing companies to manage multi requirements of their business with an easy-to-use & all-in-one SAP Business One manufacturing.

Benefits of SAP Business One ERP Manufacturing

Here’s why choosing manufacturing ERP is a smart choice

Uneecops is your trusted SAP Partner

We’re honored by SAP as the best SAP Partner in India.

SAP Business One

APJ Partner of the Year (Asia Pacific & Japan)

2023SAP Business One

Partner of the Year, India

2023Choosing Manufacturing ERP - Why Do You Need It?

The face of the manufacturing industry is facing the increasing complexity, production processes, adoption of new laws, new advances in raw materials, space constraints and product life cycles. With the growing number of laws and strict compliance and a number of industry regulations and increasing customer expectations, manufacturing companies face intense numerous challenges. Apart from these ongoing challenges one of the most daunting concerns manufacturers face is formula management and getting actionable information of logistics, cost accounting, controlling, and knowing a list of raw materials that may be hazardous for human lives, environmental, and other related challenges. With so many strict industry standards to adhere to, there comes the need to bring in robust and enterprise-ready ERP software for manufacturing industry that can help you meet your today’s and future business demands. The best ERP for manufacturing can help you in work schedule management, physical counting, replenishment, multilevel warehousing, and location management. This is where Uneecops ERP for industrial manufacturing industry in India becomes your partner of choice.

Get DemoTypes of Manufacturing SAP Business One Implementation

For ERP implementation in manufacturing industry, you can opt amongst two deployment models

Manufacturing ERP Software India: The Uneecops Edge

Uneecops, being “Asia’s #1 SAP Business One Partner” and ”India’s first Platinum SAP BI partner” is your go-to ERP partner!

Uneecops is the top SAP Platinum partner in India with SAP B1 market presence of more than 60%. Being awarded as the SAP Business One #1 partner for 09 years in a row, we have gone ahead to be the finalist of Pinnacle Awards for driving exceptional customer success. Further, with our commitment and relentless drive to be the number one SAP Business One partner, we have achieved the coveted award of being Asia’s 1 SAP Business One Partner 2018. Uneecops has also a decade-long successful history of rendering services from implementation, customization, support, managed services, cloud hosting, HANA, and migration services. As an SAP MVAR, we have over 100+ SAP Business One channel partners across India and the peninsula of Asia. Looking for SAP for small manufacturing business? With our industry experience, you gain unrivalled industry service and support. Get set, Get SAP!

Features of SAP Business One for Manufacturing

Meet your industry challenges with cloud-based manufacturing ERP software.

Machine Planning Processes

Machine Planning Processes

Reduce overspending and inefficiencies throughout the entire production process. Increase cost-savings as you plan better with accurate resources and machine planning processes with SAP Business One for manufacturing industry.

Warehouse Management

Warehouse Management

Manage inventory across multiple warehouses and maintain cost-effective production with advanced warehouse and bin location tracking. Manufacturing ERP software helps effortlessly track stock movements, improve delivery time & reduce stock-outs.

APPP (Articulated Production Planning Process)

APPP (Articulated Production Planning Process)

Includes discrete manufacturing. This will be well integrated with PLC (Product Life Cycle) stages autonomously as well as merged with interdependent processes.

The ING’s Processes

The ING’s Processes

The additive, casting, imaging, molding, forming, machining, joining and other related processes run via SAP Business One platform and Uneecops’s specially designed add-ons.

(IIRM) Information Integration & Response Module

(IIRM) Information Integration & Response Module

The processes are tapped via specific add-ons and configuration processes which enables the unhindered flow of information at various departments. This includes SMS, eMail etc.

Production Project Management

Production Project Management

Always in the know of all projects with real-time, cross-functional reporting including manufacturing and logistics management, cost accounting, controlling, and more.

Actual costs and estimates

Actual costs and estimates

Easily calculate profit margins with inbuilt functionality and supported add-ons. An analytical inbuilt in SAP Business One facilitates the predictions on machine and resources.

Key Product Costings

Key Product Costings

The availability of structured data and values (material masters, BOM, routing, system driven pricing, real-time calculation engine HANA) with integrated figures makes it possible to get the best out of production, inventory, engineering and all-rounded costs.

Quality control

Quality control

Since SAP Business One uses preset configurations it’s easy to monitor the quality based on international standards which include generating the certificates and labels automatically.

Dashboard cockpit

Dashboard cockpit

Get the much-needed visibility and control at work with SAP B1 Dashboard. Visualize your business data, drill down into critical processes and make informed decisions with SAP Business One for manufacturing industry.

Planning and consumption

Planning and consumption

With “over-the-shelf-availability” of material and resources, amalgamated with the best practices, it is possible to plan JIT, FIFO while maintaining the optimum use of the same. This includes lead times, transferring schedules, capacities of machine, resources, BOMs and Batches to name a few.

Endemic Production Cycle

Endemic Production Cycle

Niche area where a typical process is used to accommodate specific requirements that are unique to the production. ERP for manufacturing companies helps gain end-to-end visibility across production processes while adhering to quality and safety.